Top Waste Tyre Recycling Plant Manufacturer | Complete Rubber Recycling Solutions

- Furein is a leading manufacturer specializing in waste tyre recycling plants. We recycle all kinds of rubber-containing waste tyres, such as car tyres, sedan tyres, truck tyres, steel-belted tyres, and fiber tyres.

- Whether it is a semi-automatic waste tire recycling machinery or a fully automatic rubber tire recycling line, through multi-stage separation technology, it can ensure that the purity of steel wire recycling is ≥99.5% and the cleanliness of rubber particles is more than 98%.

- It can be customized to meet different production capacity requirements and provide a complete tire recycling rubber particles/power plant solution from raw material processing to finished product screening.

- The equipment is equipped with an emergency stop button and a photoelectric sensor device, which can realize the safety monitoring of the whole tire recycling production line.

Waste Tyre Recycling Plant For Sale

Come see our ready-to-roll used tire recycling plant in action! This tire recycling machinery turns scrap tires into cash-worthy granules or powder - giving old rubber a brand-new life. It is ready for immediate use. For detailed specifications or to discuss implementation, please contact us to begin planning your tire recycling project.

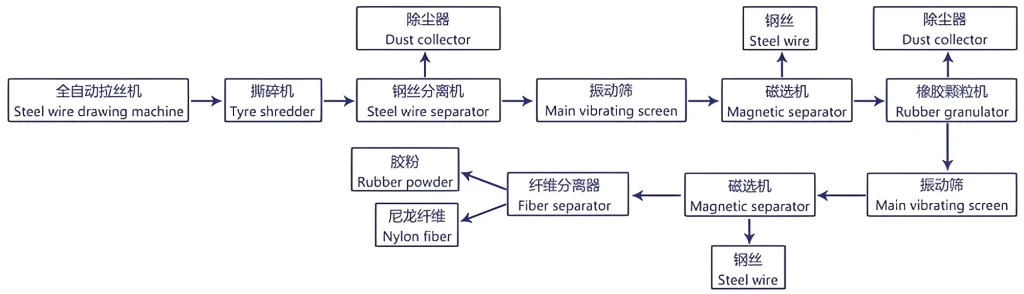

Industrial Process of Waste Tire Recycling Plant

Waste tire recycling plant is a complete system that uses various equipment, including tyre balers, tyre debeaders (tyre pullers), tyre cutters, tyre shredders, steel separators (raspers), rubber granulators, magnetic separators, rubber granule screeners, rubber grinders, conveyors, dust collectors, fiber separators, and rubber product presses, etc.. Waste tyre recycling plants have two types: full auto and semi-automatic. But generally includes the following steps:

- Remove the steel rim and cut the tyre into sections.

- Tear the tyre or its pieces into smaller chunks.

- Grind the chunks into rubber mulch, removing most of the steel wires.

- Get rid of any remaining metal and fibers embedded in the tyre.

- Turn the rubber mulch into rubber granules.

- Grind the pure rubber granules into fine rubber powder.

- Depending on your needs and budget, you can choose between a fully automatic waste tyre recycling plant or a semi-automatic one.

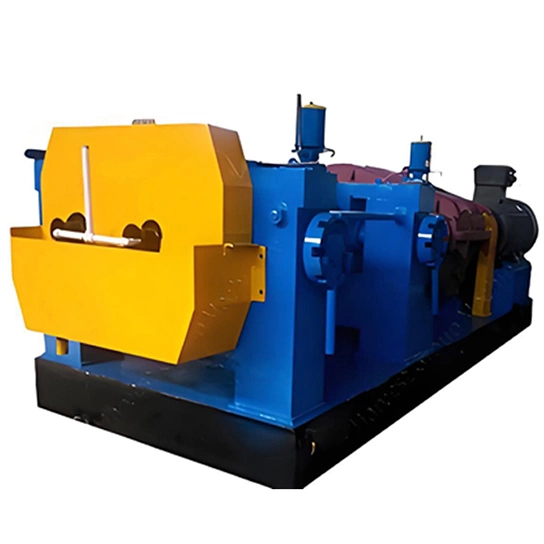

Full Automatic Wate Tyre Recycling Plant For Sale

FUREIN‘s fully automatic waste tyre recycling plant intelligent PLC control and modular design, enables processing of 1-10 tons/day for various scrap tires (car/truck/OTR). Customizable configurations adapt to diverse production scales, delivering complete solutions from tires processing to finished product(particle/powder) sorting for large-volume tire recycling.

Automatic Steel Wire Drawing Machine

Furein's steel wire drawing machine uses lasers and two hydraulic arms to pull steel wires out of tires (14"-24" sizes) in just 60 artículos de segunda clase. Its special blades prevent clogs, ensuring all wire is removed, leaving clean tires ready for shredding.

Waste Tyre Shredder Machine

Furein's double-shaft waste tire shredder machine cuts whole tires into small 3-8cm rubber pieces. It has tough blades that last 2000 hours and can handle 5-8 tons per hour. If metal gets stuck, it automatically reverses to protect itself.

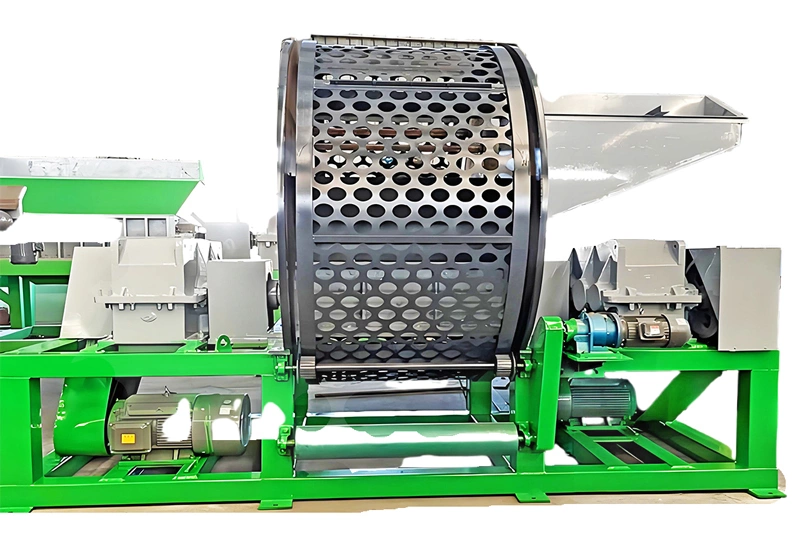

Tyre Steel Wire Separator

Furein's steel wire separator turns 100mm tire chunks into 10-15mm granules using shaking screens and air separation. Its unique blades fully separate rubber from steel, processing 3-5 tons per hour, even for truck tires with lots of steel.

Magnetic Separator For Tires

It can separate the steel wire and rubber in the tire. With a super-strong 12,000 Gauss magnet, this machine removes 99.9% of tiny steel wires (as small as 0.1mm). It cleans itself and can adjust its angle (15°-45°) to match the material flow.

Rubber Granulator Machine

With its own internal water cooling system, the rubber temperature is kept below 60℃ during the process of making tire into particles/powder, built-in air classification removes 99% fibers with 2-3t/h processing capacity.

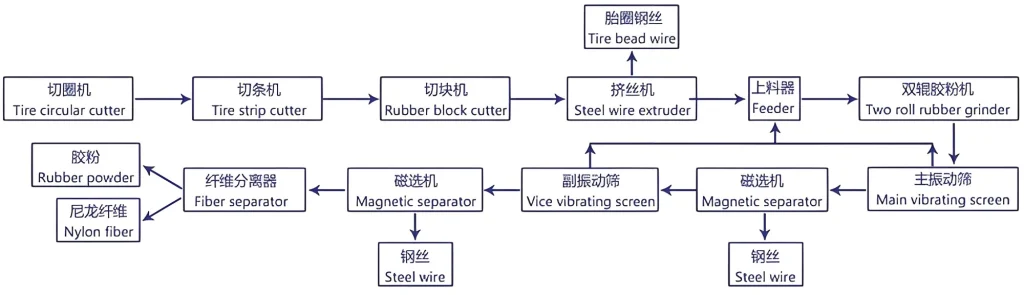

Key Parameter of Semi-automatic Waste Tire Recycling Line

Furein's semi-automatic waste tire recycling line mixes manual work with machines, perfect for small to medium recyclers. It processes 5-15 tons of tires (car, truck, or motorcycle) per day, turning them into 10-30 mesh rubber powder. Its modular setup lets you expand step-by-step, cutting startup costs by over 40%. With safety features and easy controls, it’s simple to maintain—great for beginners.

Used Tire Sidewall Cutter For Sale

Sometimes also called it tire sidewall cutter, workers lock tires onto spinning hydraulic blades to cut out the beads in 30-50 artículos de segunda clase. The tire bead cutter fits tires from 12" a 26.5" and leaves less than 5% rubber behind. The strong cast iron frame and 7.5kW motor make it tough and reliable.

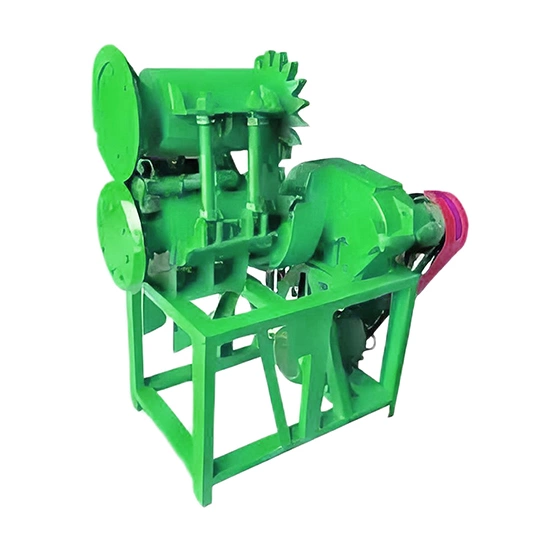

Tire Steel Removing Machine

Two rollers of tire steel separator press down with 5-20MPa force to pull wires from tire beads. You feed it by hand and watch the pressure gauge. It recovers 98% of the wire, handling 200-300kg per hour.

Tire Strip Cutting Machine

Furein's tire strip cutting machine cuts tires (without beads) into 50mm-wide strips. Its 2.2kW motor and replaceable blades process 1-2 tons per hour, keeping cuts within 3mm accuracy.

Tire Block Cutter

Cross-cutting blades chop strips into 25x25mm blocks. A hydraulic system protects the blades from metal bits, and the open design makes cleaning easy.

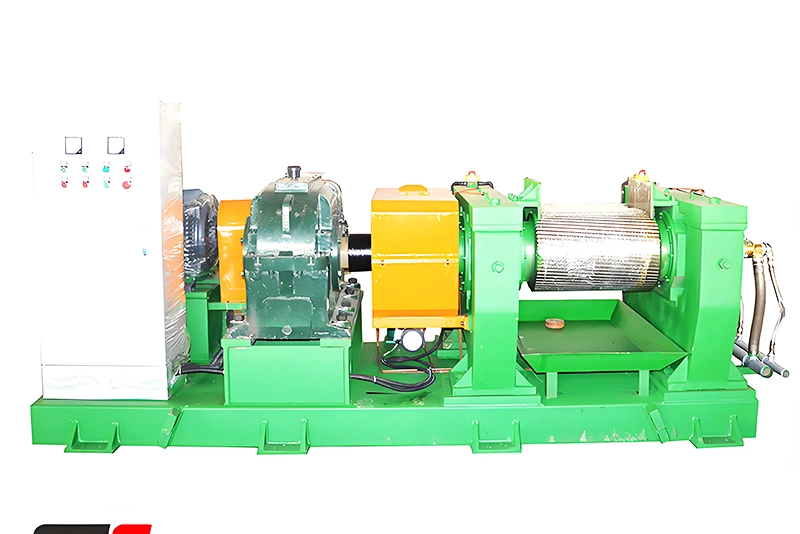

Rubber Roller Grinding Machine

Adjustable 0.1-5mm roller gap grinds rubber into powder using friction heat. Manual pressure control produces 10-30 mesh powder at 85% yield rate. 22kW motor with air cooling system.

Technical Specifications for Waste Tyre Recycling Line Manufacturing Process

| Feature | Description |

|---|---|

| Applicable Industries | Waste tire production process, waste rubber process, and waste tire recycling machine manufacturer |

| Condition | New |

| Type | Waste tires/rubbers manufacturing process |

| Production Capacity | 0.5-10 tons per hour |

| Place of Origin | Henan, China |

| Voltage | Adjustable |

| Power(W) | Determined by its degree of automation, higher automation, higher power, and different solutions with different power |

| Weight | 1000kg-10000kg |

| Certification | ISO CE SGS |

| Warranty | 1 YEAR |

| After-sales Service Provided | Field installation, commissioning and training, Engineers available to service machinery overseas |

| Energy | Hydraulic |

| Raw material | Waste tires/rubbers |

| Application | Waste tire recycling plant, rubber recycling machine |

| Motor | SIEMENS, and China brands |

Unlock More Secrets About Waste Tire Recycling Production Lines

Furein is a professional waste tire recycling machine manufacturer who can provide you with customized solutions. Furein team offer one-on-one service and layout drawings for both automatic and semi-automatic waste tire rubber recycling plant. Contact us to learn more about tyre recycling plant prices.

Welcome to our waste tyre recycling plant factory

Why choose Furein's waste tire recycling plants?

- It can process tires and rubber products of different sizes and recycle rubber into granules or powder.

- It is highly customizable, with different solutions for different outputs. It is flexible and easy to use.

- The modular unit can be started semi-automatically and upgraded to fully automatic.

- Through the optimized motor design, it saves 30% of electricity compared to traditional plants.

- In addition to mechanical equipment, there is also suitable production line guidance.