Tire Baler Machine For Sale

A tire baler machine is a kind of equipment for centralized recycling of waste tires, which can press down vertically, compressing hundreds of tires into a bale block for easy transportation. The tire baler machine is widely used in automobile factories, steel mills, ports and other places where there are large quantities of waste tires.

Tire balers are ideal for handling large quantities of tires quickly at an affordable cost. These machines are designed to crush and bale up to nine hundred tires per hour!

Tire baling machines are used to compress old or discarded tires into blocks that can then be processed and recycled into new rubber products. Tire baling machines are also known as tire recycling machines and tire recycling plants.

A vertical pressing type tire baler is mainly used to compress waste tires by pushing them downward with a large number of rollers. The machine adopts a single-cylinder hydraulic system to drive the rollers.

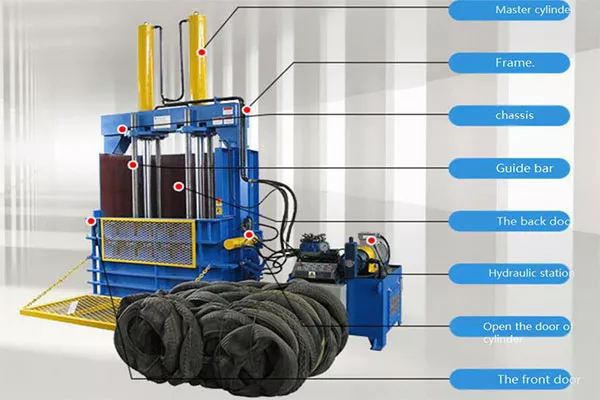

Scrap Tire Baler Machine Parts

The waste tire baler is mainly composed of a hydraulic cylinder, frame, chassis, control rod, hydraulic door, cylinder, electric control cabinet, etc..

The electric control cabinet is composed of a PLC control unit and touch screen panel, which can realize automatic operation according to the customer’s requirements.

The waste tire baler adopts a modularized structure design for easy maintenance and replacement of parts.

The core components of the waste tire baler are the machine frame and hydraulic cylinder. The machine frame is made of a high-strength steel plate with high quality welded structure.

How does a tire baler machine work?

Primero, add hydraulic oil and put the scrap tires inside the baler. After the material bin is filled, start the remote control switch and start automatic compression, followed by manual or automatic rope bundling, and a tire bale is finished.

Main Parts of Tire Baler Machine

Main hydraulic cylinder

Compression chamber

Hydraulic station

Safety door

The hydraulic baler has strong pressure, which can compress not only waste tires together, but also cardboards, plásticos de desecho, textiles, etc.. It can really realize one machine with multiple uses.

Tire baler parameters

- Model FU-1000 parameter:

- Bale size: Length:60 inch; Width: 30inch; Height:24-50inch.

- The weight of each bale is 1700-2600 lbs.

- The output can reach 2-3 bales per hour.

- Steel wire strapping is used.

The Tire Baler is a vertical down-stroke portable baler that compresses approximately 100 whole car tires into a bale measuring 60" X 30" X 50".

Two stable workers can complete 3 bales in one hour.

In addition to baling scrap tires, other items, como cartón, ropa vieja, chatarra, etc., can be recycled.

The baled tire is easily transported by forklift to the warehouse and disposed of centrally.

Advantages of tire baler

The Tire Baler can improve workplace safety and reduce fire hazards by recycling tires, rubber products and other solid waste.

The Tire Baler is a fully automated system that handles tires and rubber products. It reduces labour costs and disposal costs while increasing revenue generation.

With a tire baler, you don't have to dispose of used tires and rubber products in landfills and junkyards.

Convert used tires and rubber products into high-quality road materials (such as asphalt and concrete).

Tire balers are designed to bring your scrap tire and rubber product disposal business into the 21st century by providing a safe, cost-effective and profitable method of scrap tire destruction. With a tire baler, you can reduce waste costs by as much as 60%.

Can a tire baler baling truck tires?

A tire baler can't be used to baling truck tires; The truck tire will exceed the maximum capacity of the baler, which can't handle it.

The best thing to do is to cut the truck tires into pieces before balancing them. It will become more accessible than when you try to use a tire baler for truck tires.

Why should waste tires be recycled?

1. To save resources

2. Recycle and reuse resources

3. Reduce pollution